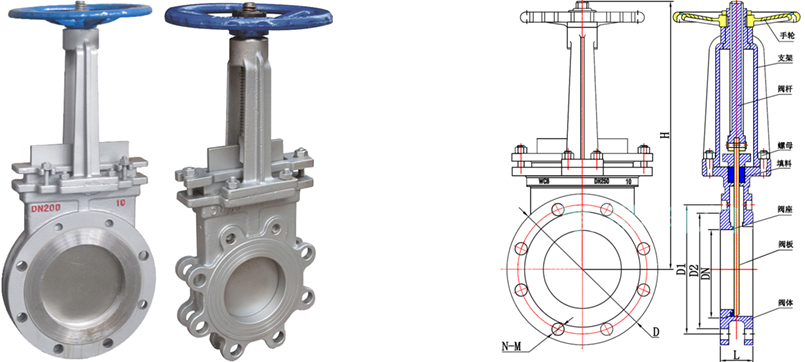

手动对夹式刀型闸阀安装尺寸以及外形图

发布时间:2016-05-30 10:38 已被浏览 次

刀型闸阀产品概述

刀型闸阀产品概述

刀型闸阀,又称刀闸阀或刀型浆闸阀。其应用范围非常广泛,从矿山、电厂的选煤、排矸、排渣,到城市的污水处理;从水泥、造纸厂的浆液输送,到食品、卫生、医药等专业管道。超薄设计的刀型闸阀以其体积小、重量轻、阻流小、不积渣,易安装,易拆卸的优点彻底解决了普通闸阀、平板闸阀、球阀、截止阀、调节阀、蝶阀等阀门的阻流大,占空间,易积渣,不易安装和维修等疑难问题。因而大量的通用切断类阀和调节型阀门被刀型闸阀取代。

产品概述

产品概述

手动对夹式刀型闸阀又叫手动插板阀或手动闸板阀,适用于糖浆、纸浆、污水、煤浆、灰渣、粉尘、渣水混合物等介质管道,可作为介质切断和节流使用,该刀型闸阀适合水平安装,亦倾斜安装。

技术参数范围

技术参数范围

公称压力:0.6MPa、1.0MPa、1.6MPa、2.5MPa、150LB

公称通径:DN50mm~DN2000mm NPS 2"~80"

适用温度:-38℃~1100℃(具体温度范围视密封副材质和介质性质而定)

连接法兰:ANSI B16.5、GB/T9113、JB/T79、HG、SH、JIS、DIN、NF、BS

主体材料:C.I、WCB、ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti、CF8、CF8M、CF3、CF3M、2Cr25Ni20

密封形式:硬密封、软密封

泄 漏 量:硬密封:D级(液体0.1×DNmm3/s);软密封:A级(零泄漏)

配套附件:安装法兰

Knife Gate Valve Product Introduction

Knife Gate Valve Product Introduction

Type knife gate valve, also known as the knife gate valve or knife gate valve type pulp. Its application scope is very broad, from coal mines, power plants, slag discharge, discharging the gangue, the city sewage treatment; From the cement slurry transportation, paper mills, to food, health, medicine and other professional pipeline. Ultra-thin design type knife gate valve with its small volume, light weight, small flow resistance, no slag, easy to install, easy to remove completely solve the advantages of the common gate valve, flat gate valve, ball valve, globe valve, regulating valve, butterfly valve, choke valve, occupy a space, easy slag deposition, not easy to install and maintenance problems. So a lot of general cut off valve and external regulation valve replaced by type knife gate valve.

Product Introduction

Product Introduction

The valve is suatable for pipeline conveying such mediums including syrup,paper pulp,sludge,sewage,coal slurry,etc.for controlling switching on/off and throttling.it allows horizontal mounting as well as in clined mounting.

Technical Parameter Range

Technical Parameter Range

Nominal pressure:0.6MPa、1.0MPa、1.6MPa、2.5MPa、150LB

Nominal diameter:DN50mm~DN2000mm NPS 2"~80"

Suitable temperature:-38℃~1100℃(Range of temperature subject to the material of sealing and property of medium)

Flange drilling:ANSI B16.5、GB/T9113、JB/T79、HG、SH、JIS、DIN、NF、BS

Main materials:C.I、WCB、ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti、CF8、CF8M、CF3、CF3M、2Cr25Ni20

Seal type:Stainless steel hard seal、Teflon soft seal

Leakage:Stainless steel hard seal:Grade D(Liquid0.1×DNmm3/s)、Teflon soft seal:Grade A(Zero Leakage)

Accessories:Flange

设计制造Design and manufacture: JB/T8691-1998

法兰连接Flange connection: GB/T9113.1-2000 JB/T79-94

结构长度Stuctural length: GB/T15188.2-94

试验验收Testing and acceptance: GB/T13927-92

主要零部件材质Key parts material 主要零部件材质Key parts material |

|

主要性能规范Key performance indicators 主要性能规范Key performance indicators |

阀体、上盖

body,upper cap |

碳钢、不锈钢

Carbon steel,stainless steel |

|

公称压力

Nominal pressure |

PN |

阀板

Valve plate |

不锈钢

Stainless steel |

|

壳体试验

Casing test |

1.5×PN |

阀杆

Stem |

不锈钢

Stainless steel |

|

密封试验

Leak test |

1.1×PN |

密封圈

Seal ring |

橡胶、四氟、不锈钢、硬质合金

Rubber,PTFE,stainless steel,hard alloy |

|

工作温度

Operating temperature |

橡胶≤80℃,四氟密封≤180℃,硬密封≤425℃

Rubber ≤80℃,PTFE≤180℃,hard sealing ≤425℃ |

|

|

|

|

适用介质

Working medium |

糖浆、纸浆、污水、煤浆、灰、渣水混合物

Syrup,paper pulp,sewage,coal slurry,dust,slag-water mix |

主要外形及连接尺寸Profile and connection dimension 主要外形及连接尺寸Profile and connection dimension |

单位Unit:mm 单位Unit:mm

|

|

PN |

DN |

L |

D |

D1 |

D2 |

H |

N-M |

PN |

DN |

L |

D |

D1 |

D2 |

H |

N-M |

|

0.6 |

50 |

48 |

160 |

125 |

100 |

370 |

4-16 |

1.0 |

50 |

48 |

160 |

125 |

99 |

370 |

4-16 |

|

65 |

48 |

180 |

145 |

120 |

400 |

4-16 |

65 |

48 |

185 |

145 |

120 |

400 |

4-16 |

|

80 |

50 |

195 |

160 |

135 |

440 |

4-16 |

80 |

50 |

200 |

160 |

135 |

440 |

8-16 |

|

100 |

50 |

215 |

180 |

155 |

510 |

8-16 |

100 |

50 |

220 |

180 |

155 |

510 |

8-16 |

|

125 |

57 |

245 |

210 |

185 |

580 |

8-16 |

125 |

57 |

250 |

210 |

185 |

580 |

8-16 |

|

150 |

57 |

280 |

240 |

210 |

690 |

8-20 |

150 |

57 |

285 |

240 |

210 |

690 |

8-20 |

|

200 |

70 |

335 |

295 |

265 |

800 |

8-20 |

200 |

70 |

340 |

295 |

265 |

800 |

12-20 |

|

250 |

70 |

390 |

350 |

320 |

960 |

12-20 |

250 |

70 |

405 |

355 |

310 |

960 |

12-22 |

|

300 |

76 |

440 |

400 |

368 |

1200 |

12-20 |

300 |

76 |

460 |

410 |

375 |

1200 |

12-22 |

|

350 |

76 |

500 |

460 |

428 |

1360 |

16-20 |

350 |

76 |

520 |

470 |

435 |

1360 |

16-22 |

|

400 |

89 |

565 |

515 |

482 |

1550 |

16-22 |

400 |

89 |

580 |

525 |

485 |

1550 |

16-27 |

|

450 |

89 |

615 |

565 |

532 |

1700 |

20-22 |

450 |

89 |

640 |

585 |

545 |

1700 |

20-27 |

|

500 |

114 |

670 |

620 |

585 |

1900 |

20-22 |

500 |

114 |

715 |

650 |

609 |

1900 |

20-30 |

|

600 |

114 |

780 |

725 |

685 |

2400 |

20-27 |

600 |

114 |

840 |

770 |

720 |

2400 |

20-36 |

|

700 |

130 |

895 |

840 |

800 |

2600 |

24-27 |

700 |

130 |

910 |

840 |

788 |

2600 |

24-36 |

|

800 |

130 |

1010 |

950 |

898 |

2700 |

24-30 |

800 |

130 |

1025 |

950 |

895 |

2700 |

24-36 |

|

900 |

140 |

1110 |

1050 |

1005 |

3100 |

28-30 |

900 |

140 |

1125 |

1050 |

998 |

3100 |

28-36 |

|

1000 |

216 |

1220 |

1160 |

1115 |

3600 |

28-30 |

1000 |

216 |

1255 |

1170 |

1110 |

3600 |

28-42 |

|

1200 |

254 |

1450 |

1380 |

1325 |

4300 |

32-36 |

1200 |

254 |

1485 |

1390 |

1325 |

4300 |

32-48 |

【声明】: 以上文章或资料除注明为西安克莱斯自动化科技有限公司自创或编辑整理外,均为各方收集或网友推荐所得。其中摘录的内容以共享、研究为目的,不存在任何商业考虑。

目前网站上有些文章未注明作者或出处,甚至标注错误,此类情况出现并非不尊重作者及出处网站,而是因为有些资料来源的不规范。如果有了解作者或出处的原作者或网友,请告知,本网站将立即更正注明,并向作者道歉。

被摘录的对象如有任何异议,请与本站联系,联系邮箱:a59168@126.com,本站确认后将立即撤下。谢谢您的支持与理解!

刀型闸阀产品概述

刀型闸阀产品概述 产品概述

产品概述 技术参数范围

技术参数范围 Knife Gate Valve Product Introduction

Knife Gate Valve Product Introduction Product Introduction

Product Introduction Technical Parameter Range

Technical Parameter Range

主要零部件材质Key parts material

主要零部件材质Key parts material 主要性能规范Key performance indicators

主要性能规范Key performance indicators 主要外形及连接尺寸Profile and connection dimension

主要外形及连接尺寸Profile and connection dimension 单位Unit:mm

单位Unit:mm