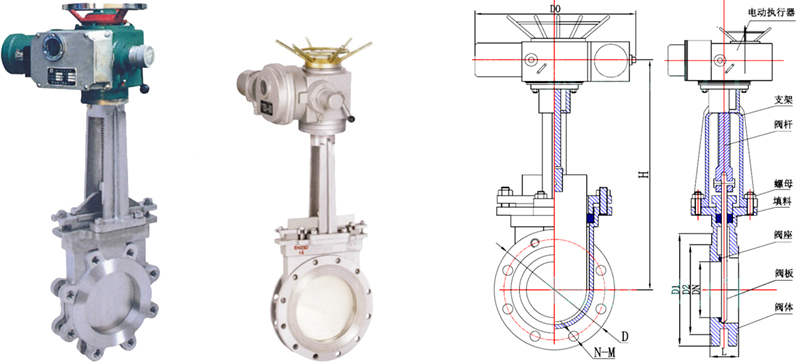

电动刀型闸阀安装尺寸以及外形图

发布时间:2016-05-30 11:22 已被浏览 次

电动刀型闸阀产品概述

电动刀型闸阀产品概述

电动刀型闸阀,又称刀闸阀或刀型浆闸阀。其应用范围非常广泛,从矿山、电厂的选煤、排矸、排渣,到城市的污水处理;从水泥、造纸厂的浆液输送,到食品、卫生、医药等专业管道。超薄设计的电动刀型闸阀以其体积小、重量轻、阻流小、不积渣,易安装,易拆卸的优点彻底解决了普通闸阀、平板闸阀、球阀、截止阀、调节阀、蝶阀等阀门的阻流大,占空间,易积渣,不易安装和维修等疑难问题。因而大量的通用切断类阀和调节型阀门被电动刀型闸阀取代。

产品概述

产品概述

电动刀型闸阀采用多回转电动装置,用以驱动和控制阀门的开启和关闭,操作人员可以在控制室内远距离对阀门进行控制,也可以现场手动操作,也可以与计算机配合实现计算机自动控制。

技术参数范围

技术参数范围

公称压力:0.6MPa、1.0MPa、1.6MPa、2.5MPa、150LB

公称通径:DN50mm~DN2000mm NPS 2"~80"

适用温度:-38℃~1100℃(具体温度范围视密封副材质和介质性质而定)

连接法兰:ANSI B16.5、GB/T9113、JB/T79、HG、SH、JIS、DIN、NF、BS

主体材料:C.I、WCB、ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti、CF8、CF8M、CF3、CF3M、2Cr25Ni20

密封形式:硬密封、软密封

泄 漏 量:硬密封:D级(液体0.1×DNmm3/s);软密封:A级(零泄漏)

配套附件:安装法兰

电动装置参数

电动装置参数

1、电源:AC380V、50HZ

2、标准型:标准型产品具有防尘、防雨水的外壳 保护能力、保护等级IP65,可直接用于户外

3、防水型:产品具有防尘、防浸水(IP67)的外壳防护等级

4、防爆型(EX):防爆等为DⅡ BT4/DⅡ CT4(不含乙炔)

5、环境温度:-20℃~40℃

6、可选:配电气控制器

产品特性

产品特性

1、启闭迅速,平衡可靠,自动化程度高

2、安装高度及位置不受限制

3、采用防爆型电动装置,在易燃易爆,甚至有毒气体环境中可以正常工作

4、配有手动,万一供电间断,可以手动操作开启或关闭阀门,有效控制介质,防止事故发生

Knife Gate Valve Product Introduction

Knife Gate Valve Product Introduction

Type knife gate valve, also known as the knife gate valve or knife gate valve type pulp. Its application scope is very broad, from coal mines, power plants, slag discharge, discharging the gangue, the city sewage treatment; From the cement slurry transportation, paper mills, to food, health, medicine and other professional pipeline. Ultra-thin design type knife gate valve with its small volume, light weight, small flow resistance, no slag, easy to install, easy to remove completely solve the advantages of the common gate valve, flat gate valve, ball valve, globe valve, regulating valve, butterfly valve, choke valve, occupy a space, easy slag deposition, not easy to install and maintenance problems. So a lot of general cut off valve and external regulation valve replaced by type knife gate valve.

Product Introduction

Product Introduction

Type electric knife gate valve adopts multi-turn electric device, is used to drive and control the opening and closing of the valve, operators can to control the valve in the control room distance, can also be the scene manual operation, can also cooperate with computer to realize computer automatic control.

Technical Parameter Range

Technical Parameter Range

Nominal pressure:0.6MPa、1.0MPa、1.6MPa、2.5MPa、150LB

Nominal diameter:DN50mm~DN2000mm NPS 2"~80"

Suitable temperature:-38℃~1100℃(Range of temperature subject to the material of sealing and property of medium)

Flange drilling:ANSI B16.5、GB/T9113、JB/T79、HG、SH、JIS、DIN、NF、BS

Main materials:C.I、WCB、ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti、CF8、CF8M、CF3、CF3M、2Cr25Ni20

Seal type:Stainless steel hard seal、Teflon soft seal

Leakage:Stainless steel hard seal:Grade D(Liquid0.1×DNmm3/s)、Teflon soft seal:Grade A(Zero Leakage)

Accessories:Flange

Electric device parameters

Electric device parameters

Power supply: AC380AV, 50HZ.

Standard type: Standard type is equipped with dust-resistant, rain-proof casing. The protective level is IP65. It could be used directly outdoors.

Waterproof type: The casing is resistant to dust and water immersion (IP67 protective level).

Explosion-proof type (EX) DII BT4/DII CT4 explosion-proof level (excluding acetylene).

Ambient temperature: -20~40°C.

Optional: electrical controller

Optional accessories

Optional accessories

1、Quick switching on/off, reliability, equilibrium, high level of automation.

2、Unlimited installation height and position.

3、Explosion-proof electric device that allows normal operation in inflammable and explosive environment or environment with poisonous gas.

4、Manual operating mechanism allowing manual switching on/off of the valve in case of power failure. The medium will be controlled effectively for prevention against accident.

|

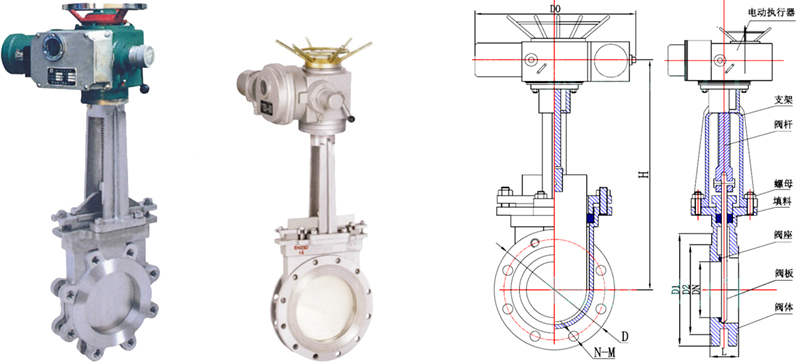

主要外形及连接尺寸Profile and connection dimension 主要外形及连接尺寸Profile and connection dimension |

单位Unit:mm 单位Unit:mm

|

|

PN |

DN |

L |

D |

D1 |

D2 |

H |

N-M |

PN |

DN |

L |

D |

D1 |

D2 |

H |

N-M |

|

0.6 |

150 |

57 |

280 |

240 |

210 |

980 |

8-20 |

1.0 |

150 |

57 |

285 |

240 |

210 |

980 |

8-20 |

|

200 |

70 |

335 |

295 |

265 |

1055 |

8-20 |

200 |

70 |

340 |

295 |

265 |

1055 |

12-20 |

|

250 |

70 |

390 |

350 |

320 |

1060 |

12-20 |

250 |

70 |

405 |

355 |

310 |

1060 |

12-22 |

|

300 |

76 |

440 |

400 |

368 |

1230 |

12-20 |

300 |

76 |

460 |

410 |

375 |

1230 |

12-22 |

|

350 |

76 |

500 |

460 |

428 |

1250 |

16-20 |

350 |

76 |

520 |

470 |

435 |

1250 |

16-22 |

|

400 |

89 |

565 |

515 |

482 |

1767 |

16-22 |

400 |

89 |

580 |

525 |

485 |

1767 |

16-27 |

|

450 |

89 |

615 |

565 |

532 |

1920 |

20-22 |

450 |

89 |

640 |

585 |

545 |

1920 |

20-27 |

|

500 |

114 |

670 |

620 |

585 |

2010 |

20-22 |

500 |

114 |

715 |

650 |

609 |

2010 |

20-30 |

|

600 |

114 |

780 |

725 |

685 |

2110 |

20-27 |

600 |

114 |

840 |

770 |

720 |

2110 |

20-36 |

|

700 |

130 |

895 |

840 |

800 |

2400 |

24-27 |

700 |

130 |

910 |

840 |

788 |

2400 |

24-36 |

|

800 |

130 |

1010 |

950 |

898 |

2800 |

24-30 |

800 |

130 |

1025 |

950 |

895 |

2800 |

24-36 |

|

900 |

140 |

1110 |

1050 |

1005 |

3000 |

28-30 |

900 |

140 |

1125 |

1050 |

998 |

3000 |

28-36 |

|

1000 |

216 |

1220 |

1160 |

1115 |

3400 |

28-30 |

1000 |

216 |

1255 |

1170 |

1110 |

3400 |

28-42 |

|

1200 |

254 |

1450 |

1380 |

1325 |

3900 |

32-36 |

1200 |

254 |

1485 |

1390 |

1325 |

3900 |

32-48 |

【声明】: 以上文章或资料除注明为西安克莱斯自动化科技有限公司自创或编辑整理外,均为各方收集或网友推荐所得。其中摘录的内容以共享、研究为目的,不存在任何商业考虑。

目前网站上有些文章未注明作者或出处,甚至标注错误,此类情况出现并非不尊重作者及出处网站,而是因为有些资料来源的不规范。如果有了解作者或出处的原作者或网友,请告知,本网站将立即更正注明,并向作者道歉。

被摘录的对象如有任何异议,请与本站联系,联系邮箱:a59168@126.com,本站确认后将立即撤下。谢谢您的支持与理解!

电动刀型闸阀产品概述

电动刀型闸阀产品概述 产品概述

产品概述 技术参数范围

技术参数范围 电动装置参数

电动装置参数 产品特性

产品特性 Knife Gate Valve Product Introduction

Knife Gate Valve Product Introduction Product Introduction

Product Introduction Technical Parameter Range

Technical Parameter Range Electric device parameters

Electric device parameters Optional accessories

Optional accessories

主要外形及连接尺寸Profile and connection dimension

主要外形及连接尺寸Profile and connection dimension 单位Unit:mm

单位Unit:mm