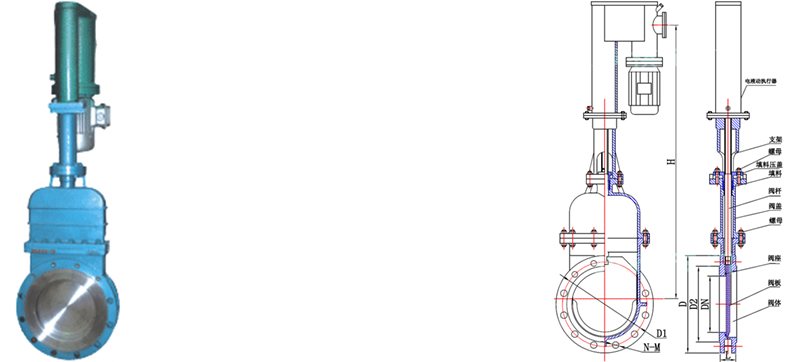

电液动暗板刀型闸阀

发布时间:2016-05-30 11:33 已被浏览 次

产品概述

产品概述

此电液动暗板刀型闸阀是闸阀中的新品种,体积小,重量轻,轻型节材,是污水、煤浆、糖浆、泥浆、空气、渣水混合物、供水、造纸、矿山等行业中的理想产品。

暗板刀型闸阀采用金属对金属的硬密封,或采用金属对橡胶的软密封。在开启和关闭的过程中,闸板与密封面采用了特殊的设计,摩擦较少,经久耐用。

此种刀形闸的上密封突破了常规的密封形式,采用上盖结构,使得上密封由大面积的矩形密封改成了小面积的圆周密封,密封性能大大提高。在圆周密封的基础上,又采用了目前国际上先进的浮动密封结构,使得上密封达到了与管道同寿命的程度,从而整体上提高了阀门的使用寿命。

此种闸阀在手轮顶部加装封套装置后,可以使阀门活动部件全部处于封闭状态,闸板和阀杆的丝杆传动不会因润滑油干枯而卡涩。特别适合在粉尘及干燥的恶劣环境中长期正常工作。

注:可根据使用单位的环境和要求来设计与生产,适合用户的安装和使用。

电液动暗板刀型闸阀通过电液联动装置往复推位来控制阀门的开启和关闭,如配置传感器或数字显示装置,可进行远距离,高空的危险地区集中或程序控制,广泛应用于冶金、电力、煤炭、矿山、水利等行业,是一种应用性强的新型更新替代产品。

技术参数范围

技术参数范围

公称压力:0.6MPa、1.0MPa、1.6MPa、2.5MPa、150LB

公称通径:DN50mm~DN2000mm NPS 2"~80"

适用温度:-38℃~1100℃(具体温度范围视密封副材质和介质性质而定)

连接法兰:ANSI B16.5、GB/T9113、JB/T79、HG、SH、JIS、DIN、NF、BS

主体材料:C.I、WCB、ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti、CF8、CF8M、CF3、CF3M、2Cr25Ni20

密封形式:硬密封、软密封

泄 漏 量:硬密封:D级(液体0.1×DNmm3/s);软密封:A级(零泄漏)

配套附件:安装法兰

电液动优点

电液动优点

1、机、电、液、仪一体化,实现现场控制,集中监控或自动控制

2、无级调力,运行平稳,冲击力小,适用于较高压力场合

3、节能,液压传动效率高达80%

4、阀门整体结构紧凑,体积小,无需液压泵站

5、可控制任意阀位并可锁定

Product introduction

Product introduction

This knife gate valve is a new generation gate valve characteristic of small construction, low weight, and high material utilization. It is an ideal product for such sectors including sewage disposal, coal slurry, syrup, sludge, air, slag-water mix, water supply, papermaking, mining, etc.

The knife gate valve adopts metal-to-metal hard sealing or metal-to-rubber soft sealing. In the processing of valve switching on/off, the gate plate and sealing face are provided with special design, featuring limited friction and high durability.

The sealing of the knife gate valve represents a breakthrough in traditional sealing form. Upper cap structure changes large area rectangular sealing face of the upper sealing to small area circular sealing, with much enhanced sealing performance. Based on circular sealing, the valve is further provided with latest floating sealing construction in the world. Thus the upper sealing shares the same useful life with pipeline, so the overall useful life of the valve increases.

After envelope is added to the top of hand wheel, all the moving parts of the gate valve will be enclosed. Therefore, the rotation of lead screws between gate plate and stem will not block because of short supply of lubricating oil. In particular, the valve is applicable for long-term service in severely dusty and dry environment.

Note: The valve could be designed and manufactured based on client's site conditions and requirements for better installation and application.

The product controls opening and closing of valve by the reciprocating pushing effect of electric-hydraulic linkage. It can bring about centralized or programmed control distantly for high-attitude dangerous area by mounting optional sensor or digital display. It is widely used in such sectors including metallurgy, electricity generation, coal mining, mining, water conservancy, etc., representing a kind of highly practical, upgraded substitute.

Technical Parameter Range

Technical Parameter Range

Nominal pressure:0.6MPa、1.0MPa、1.6MPa、2.5MPa、150LB

Nominal diameter:DN50mm~DN2000mm NPS 2"~80"

Suitable temperature:-38℃~1100℃(Range of temperature subject to the material of sealing and property of medium)

Flange drilling:ANSI B16.5、GB/T9113、JB/T79、HG、SH、JIS、DIN、NF、BS

Main materials:C.I、WCB、ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti、CF8、CF8M、CF3、CF3M、2Cr25Ni20

Seal type:Stainless steel hard seal、Teflon soft seal

Leakage:Stainless steel hard seal:Grade D(Liquid0.1×DNmm3/s)、Teflon soft seal:Grade A(Zero Leakage)

Accessories:Flange

Electric and hydraulic features

Electric and hydraulic features

|

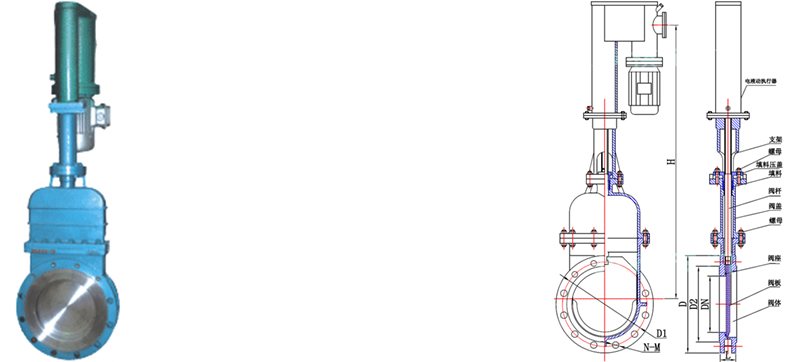

主要外形及连接尺寸Profile and connection dimension 主要外形及连接尺寸Profile and connection dimension |

单位Unit:mm 单位Unit:mm |

|

PN |

DN |

L |

D |

D1 |

D2 |

H |

N-M |

PN |

DN |

L |

D |

D1 |

D2 |

H |

N-M |

|

0.6 |

50 |

48 |

160 |

125 |

100 |

302 |

4-16 |

1.0 |

50 |

48 |

160 |

125 |

99 |

302 |

4-16 |

|

65 |

48 |

180 |

145 |

120 |

317 |

4-16 |

65 |

48 |

185 |

145 |

120 |

317 |

4-16 |

|

80 |

50 |

195 |

160 |

135 |

340 |

4-16 |

80 |

50 |

200 |

160 |

135 |

340 |

8-16 |

|

100 |

50 |

215 |

180 |

155 |

378 |

8-16 |

100 |

50 |

220 |

180 |

155 |

378 |

8-16 |

|

125 |

57 |

245 |

210 |

185 |

430 |

8-16 |

125 |

57 |

250 |

210 |

185 |

430 |

8-16 |

|

150 |

57 |

280 |

240 |

210 |

528 |

8-20 |

150 |

57 |

285 |

240 |

210 |

528 |

8-20 |

|

200 |

70 |

335 |

295 |

265 |

620 |

8-20 |

200 |

70 |

340 |

295 |

265 |

620 |

12-20 |

|

250 |

70 |

390 |

350 |

320 |

771 |

12-20 |

250 |

70 |

405 |

355 |

310 |

771 |

12-22 |

|

300 |

76 |

440 |

400 |

368 |

875 |

12-20 |

300 |

76 |

460 |

410 |

375 |

875 |

12-22 |

|

350 |

76 |

500 |

460 |

428 |

982 |

16-20 |

350 |

76 |

520 |

470 |

435 |

982 |

16-22 |

|

400 |

89 |

565 |

515 |

482 |

1245 |

16-22 |

400 |

89 |

580 |

525 |

485 |

1245 |

16-27 |

|

450 |

89 |

615 |

565 |

532 |

1338 |

20-22 |

450 |

89 |

640 |

585 |

545 |

1338 |

20-27 |

|

500 |

114 |

670 |

620 |

585 |

1465 |

20-22 |

500 |

114 |

715 |

650 |

609 |

1465 |

20-30 |

|

600 |

114 |

780 |

725 |

685 |

1658 |

20-27 |

600 |

114 |

840 |

770 |

720 |

1658 |

20-36 |

|

700 |

130 |

895 |

840 |

800 |

1900 |

24-27 |

700 |

130 |

910 |

840 |

788 |

1900 |

24-36 |

|

800 |

130 |

1010 |

950 |

898 |

2400 |

24-30 |

800 |

130 |

1025 |

950 |

895 |

2400 |

24-36 |

|

900 |

140 |

1110 |

1050 |

1005 |

2800 |

28-30 |

900 |

140 |

1125 |

1050 |

998 |

2800 |

28-36 |

|

1000 |

216 |

1220 |

1160 |

1115 |

3000 |

28-30 |

1000 |

216 |

1255 |

1170 |

1110 |

3000 |

28-42 |

|

1200 |

254 |

1450 |

1380 |

1325 |

3600 |

32-36 |

1200 |

254 |

1485 |

1390 |

1325 |

3600 |

32-48 |

【声明】: 以上文章或资料除注明为西安克莱斯自动化科技有限公司自创或编辑整理外,均为各方收集或网友推荐所得。其中摘录的内容以共享、研究为目的,不存在任何商业考虑。

目前网站上有些文章未注明作者或出处,甚至标注错误,此类情况出现并非不尊重作者及出处网站,而是因为有些资料来源的不规范。如果有了解作者或出处的原作者或网友,请告知,本网站将立即更正注明,并向作者道歉。

被摘录的对象如有任何异议,请与本站联系,联系邮箱:a59168@126.com,本站确认后将立即撤下。谢谢您的支持与理解!

产品概述

产品概述 技术参数范围

技术参数范围 电液动优点

电液动优点 Product introduction

Product introduction Technical Parameter Range

Technical Parameter Range Electric and hydraulic features

Electric and hydraulic features

主要外形及连接尺寸Profile and connection dimension

主要外形及连接尺寸Profile and connection dimension 单位Unit:mm

单位Unit:mm